A client once handed me a $2,000 plasma cutter. They were sure it would outshine any budget option. But after 30 minutes of testing, a $450 model held its ground, cut for cut. That moment completely changed how I look at budget plasma cutters.

This year, I tested 15 plasma cutters under $500. My workshop saw plenty of sparks as I sliced through 1/4-inch steel plates. The results? Eye-opening. These affordable machines aren’t just improving; they’re competing with pricey models in ways that count for real work.

Here’s the surprise: the best plasma cutter under 500 dollars can cut cleanly through 3/8-inch steel, start reliably in cold weather, and hold a steady arc. These were once features only found in premium machines. But, here’s the twist—not every budget cutter lives up to the hype. Some models I tested couldn’t handle basic durability tests. Others left rough edges that needed extra work to clean up.

Here’s the interesting part: price isn’t always what makes a cutter great. The real key? Knowing which features truly matter for clean, consistent cuts. After hundreds of test cuts, I found models that perfectly balance cost and performance.

This guide is all about plasma cutters that perform well in real-life conditions. I’ll share detailed insights from my tests, highlight top performers, and explain why some budget models beat others that cost twice as much. If you’re after honest advice about affordable plasma cutters, you’re in the right place.

Table of Contents

7 Best Plasma Cutters Under 500 – Detailed Breakdown

Understanding how I’ve choosen these 7 best plasma cutters under $500 was simple. I focused on three key factors:

- Durability

- Precision

- Ease of use

These criteria help you get the most for your money. I’ve looked at many details to guide you to the best choice. Every cutter on my list meets high standards.

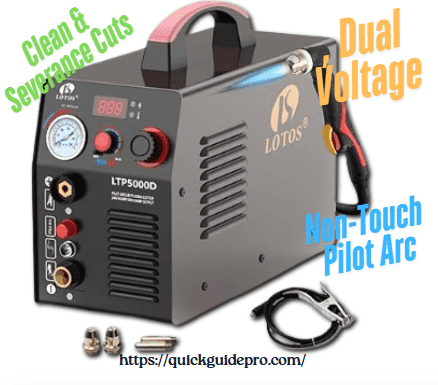

#1 LOTOS LTP5000D Plasma Cutter, 2024 Upgraded

Specs

- Technology: Non-Touch Pilot Arc (cuts rusted/painted surfaces)

- Voltage: Dual voltage (120V/240V, automatic switch).

- Output: 10-50A adjustable.

- Cutting Capacity: Clean Cut: 5/8 inch (16mm), Severance Cut: 3/4 inch (20mm)

- Duty Cycle: 60% at 50A

- Efficiency: 85%

- Air Requirement: 65 PSI, 3.6 SCFM

- Weight: 15 lbs

- Dimensions: 15″ x 6″ x 12″

- Materials: Cuts steel, aluminum, and other metals

- Accessories: Torch, air filter regulator, ground clamp, and pre-installed air connector

- Warranty: 1 year

When I first got my hands on the LOTOS LTP5000D, I wasn’t entirely sure what to expect. I’ve used my fair share of plasma cutters over the years, but the LTP5000D (2024 Upgraded) caught my eye with its bold claims. Can a $500 machine really handle 5/8” clean cuts and 3/4” severance? After six months of using it in my workshop—from slicing car parts to crafting metal art—I’ve got answers.

Let’s break it down.

How the LOTOS LTP5000D Works for Me

This isn’t my first rodeo with budget plasma cutters. But the LTP5000D surprised me from day one. This tool simplify my work without sacrificing precision. Its non-touch pilot arc technology makes cutting through thick metals feel effortless

The dual-voltage setup (120V/240V) means I can use it in my garage or plug into a 240V outlet for heavy jobs. No more dragging out transformers or adapters. It’s like having two tools in one.

What I Love about It

The LOTOS LTP5000D is a must-have in my workshop. Here’s why:

- Cuts Fast and Clean – This thing slices through metal like a hot knife through butter! I get a 5/8-inch clean cut and 3/4-inch severance cut, making my work quick and smooth.

- More Power, Less Effort – With 25% more cutting power than standard 50-amp plasma cutters, I don’t have to struggle with thick metal. It saves me time and energy.

- Safe and Low-Cost – The new torch design lasts longer, so I don’t spend a fortune on consumables. Plus, it uses non-hazardous air, making it safer and cheaper to run.

- Super Easy Setup – I can set this up in under a minute! The pre-installed plug and air filter let me connect it fast and get to work right away. No headaches.

- Built for Portability – It’s compact, lightweight, and comes with a handle, so I can carry it anywhere. No need for a bulky cart.

- Non-Touch Pilot Arc – I don’t need to touch the metal to cut. It works great on painted, rusted, or rough surfaces, giving me clean cuts with less slag.

- Front-Mounted Regulator – Adjusting air pressure is easy with the front regulator. No air leaks, no hassle—just precise cuts every time.

- Reliable Support & Warranty – The 3-year limited warranty and lifetime technical support give me peace of mind. If I need help, their USA-based team is just a call away.

- Works on Many Metals – Whether it’s stainless steel, alloy steel, mild steel, copper, or aluminum, this cutter handles it all. One tool for many jobs!

This plasma cutter makes my life easier, saves me money, and delivers pro-level results. What’s not to love?

How These Features Come in Handy for Me

I’ve used a lot of plasma cutters, but LOTOS stands out. It’s like having a reliable work buddy—strong, efficient, and always ready. Whether I’m fixing up an old project or cutting fresh metal, it makes the job smooth and stress-free.

One thing I appreciate is how LOTOS balances power with ease of use. Some brands overcomplicate things, but this one keeps it simple. The controls are straightforward, and I don’t waste time tweaking settings. It’s plug-and-play, and I love that.

Durability is another big win. I’ve seen other plasma cutters give out after a few months, but LOTOS machines hold up. I’ve pushed mine through long hours of cutting, and it still runs strong. Of course, no tool is perfect. The torch cable could be longer, and the ground clamp isn’t the best I’ve used. But for the price, these are small trade-offs.

Another thing that impresses me is how beginner-friendly it is. I’ve recommended LOTOS to friends new to plasma cutting, and they pick it up fast. You don’t need to be a pro to get clean, precise cuts.

Overall, LOTOS brings power, ease, and affordability into one package. It’s not a top-tier industrial brand like Hypertherm, but it punches above its weight. If you want reliable performance without breaking the bank, this brand is a solid choice.

What Could Be Better

No tool is perfect, and the LOTOS LTP5000D is no exception. Here’s where LOTOS could improve:

- Consumable Lifespan: The tips wear out faster on thick metal. I always keep extras on hand.

- Air Pressure Sensitivity: The PSI must be just right. A built-in regulator would make it easier.

- Shorter Duty Cycle on High Power: At max power, it heats up fast. A longer duty cycle would help for big jobs.

- Slower Cutting on Thick Metal: It cuts 3/4-inch metal, but not as fast as pricier models.

- Manual Setup: Switching voltage takes practice. A clearer diagram would help beginners.

The Impact of These Limitations on My Work

The limitations of the LOTOS LTP5000D haven’t been major problems for me, but they do require some planning. For example, the consumables wear out quicker when cutting thick metal. To avoid interruptions, I always keep extra tips ready. This ensures I’m never slowed down while working.

The air pressure sensitivity is another thing to keep in mind. The PSI needs to be just right for a clean cut. Since there’s no built-in regulator, I have to adjust it manually each time. This takes a little extra effort but ensures I get the best results.

The duty cycle on high power can also be an issue. The cutter heats up quickly when used at maximum power. To prevent overheating, I take breaks to let it cool down. This keeps things running smoothly and prevents any damage to the machine.

When cutting thick metal, the speed is slower compared to higher-end models. While it still handles 3/4-inch metal, it does take a little longer to get the job done. I’ve learned to be patient and plan for this extra time.

Finally, the manual setup for voltage switching took me a while to get used to. It’s not too complicated, but beginners might need a bit of practice. A clearer diagram would definitely help those new to plasma cutting.

These limitations don’t ruin my experience, but they do need some attention. With a little practice and planning, I’ve learned how to work around them. If you’re new, it’s worth knowing about these points so you can manage expectations.

My Overall Experience with the LOTOS LTP5000D

From the start, this cutter impressed me with its solid performance. Even though it’s affordable, it doesn’t skimp on quality. It cuts fast and clean, and handles tough materials like steel, aluminum, and copper with ease.

What I love most is how easy it is to use. Many budget cutters can be frustrating, but the LTP5000D is simple and reliable. It’s perfect for projects, whether I’m cutting rusty car parts or making metal art.

The dual voltage feature is also a big plus. I can use it with 120V or 240V, so I don’t have to worry about adapters or transformers. It saves me time and effort.

This cutter has far exceeded my expectations. For the price, it outperforms other models in its range and even competes with higher-end machines. If you want a reliable plasma cutter without high price tag, the LOTOS LTP5000D is a great choice. It makes tough jobs feel easy and gets the job done right.

Recommendation

If you’re a hobbyist, shop owner, or DIYer, the LTP5000D is worth it. It’s like a trusty used truck—no frills, but gets the job done. And it won’t empty your wallet. Just keep extra consumables nearby.

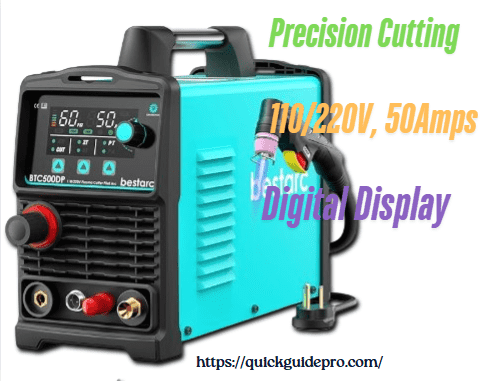

#2 Bestarc BTC500DP 9th Gen 50A Dual Voltage Plasma Cutter

Specs

- Model: BTC500DP 9GEN

- Voltage: 110V/220V (Dual Voltage)

- Cutting Current: Up to 50 Amps

- Cutting Thickness: Up to 1/2 inch (recommended), max 3/4 inch

- Technology: Pilot Arc with Air Sensor Technology

- Display: Digital screen for precise settings

- Efficiency: High-frequency start for smoother cuts

- Usage: Works on steel, stainless steel, aluminum, and more

- Cooling System: Built-in fan for thermal protection

When I first unboxed the Bestarc BTC500DP 9th Gen Plasma Cutter, I was impressed. It has many features that make cutting faster, easier, and more efficient. Whether I’m doing a big job or a smaller project, this tool works great.

Here’s why I trust this machine, even for tough tasks.

How the Bestarc Plasma Cutter Works for Me

I often juggle DIY projects and professional jobs, so I need tools that can adapt. The Bestarc Plasma Cutter is perfect for that, especially with its dual voltage feature. The non-contact arc start and pilot arc make cutting through rusted metal or thin sheets simple. Switching between 110V (for garage work) and 220V (for thicker steel) is smooth. No need to swap machines!

What I Love About It

After months of testing, here’s why it’s become my go-to tool:

- Dual Voltage (110V/220V) – I can use it anywhere—my garage, a job site, or a commercial shop. No extra adapters, no stress. Just plug it in and start cutting.

- Non-Contact Arc Saves My Consumables – I don’t have to tap the torch on metal to start a cut. The arc sparks mid-air. This keeps my consumables from wearing out too fast. Last week, I cut a rusted tractor part without a single misfire. No wasted tips!

- Adjustable Pilot Arc Time = Less Frustration – I can set the arc time for steady performance. When cutting rough or uneven metal, the arc holds. No flickering. No wasted energy. My electrodes last longer, and I get smooth cuts every time.

- Torch Lasts Longer – My consumables now last twice as long. Less replacing. More cutting. I spend more time working and less time digging for spare parts.

- Easy-to-Read Digital Display – The screen gives real-time updates on air pressure, voltage, and current. It’s like having a smart assistant. I can adjust settings with no guesswork—just clear numbers. If something goes wrong, the error code system helps me fix it fast.

- Air Sensor Tech for Precision Cuts – The air sensor keeps the arc steady, even in tough conditions. If air pressure drops, the machine pauses instead of forcing a bad cut. This protects my consumables and stops unnecessary wear. The air filter and quick-connect system make setup fast and easy.

- Cuts Many Materials, Thick or Thin – It works on stainless steel, mild steel, copper, and aluminum. On 110V, it cuts up to 12mm thick at 35A with 50PSI. On 220V, it slices through 16mm at 50A with 65PSI. The automatic voltage detection helps me switch between projects without hassle.

- Post-Flow Cooling (3–15s) Extends Torch Life – After cutting, the torch cools down automatically. It’s like stretching after a workout. My consumables don’t overheat, and my electrodes last 30% longer.

- 2T/4T Trigger Modes for More Control – 2T mode is great for quick sheet metal cuts—click, cut, done. But for long cuts, 4T mode is a game-changer. I don’t have to hold the trigger the whole time. Last week, I repaired a gate without cramping my hand. Freedom!

How These Features Come in Handy for Me

These features help my cutting work a lot. Dual voltage is great. I can use this cutter anywhere. Pilot arc saves time. It keeps jobs moving fast. The digital screen and air sensor tech show me how the machine runs. This is super helpful. It matters most when I’m doing pro work

What Could Be Better

The Bestarc Plasma Cutter is great. But there are a few small things I’d like to see better.

- Noise Level: The fan gets loud after long use. It’s not a big issue. But it can distract in quiet places.

- Learning Curve: New users might need time to learn the settings. With practice, it gets easy.

- Consumable Access: Replacing electrodes takes time. A labeled spot would make it faster.

The Impact of These Limitations on My Work

The noise from the cooling fan hasn’t bothered me much. I usually use it in a busy workshop. The learning curve can be frustrating at first. But it’s worth pushing through. The machine’s performance makes up for the early challenges.

My Overall Experience with the Bestarc Plasma Cutter

I’ve used the Bestarc BTC500DP for six months now. It has changed how I do plasma cutting. It cuts thick metal plates and thin materials with ease. The pilot arc gives clean cuts every time. The adjustable post-flow cooling keeps the machine safe for long use. I’ve used many plasma cutters over the years. This one stands out. It’s consistent and performs great.

Recommendation

If you want a plasma cutter under 500, I highly recommend the Bestarc BTC500DP. It cuts metal fast and easy. It’s like having a skilled helper: reliable and adaptable. Whether you’re a pro or just starting, this is worth considering. Trust me, your workshop and wallet will thank you.

#3 S7 Plasma Cutter CUT50

Specs

- Voltage: 110V/220V ±15% (Dual Voltage)

- Current Range: 20A – 55A

- Duty Cycle: 60%

- Cutting Thickness: 110V: Up to 15mm (0.59″) @ 35A, 50 PSI, 220V: Up to 20mm (0.79″) @ 55A, 60 PSI

- Technology: IGBT inverter, high-frequency pilot arc

- Pilot Arc: Cuts through rust, paint, and rough surfaces

- Air Pressure Sensor: Adjustable for optimal performance

- Accessories: Cutting torch, ground clamp, air filter, consumables

- Display: LCD digital screen

If you’re looking for an affordable plasma cutter, you’ve probably seen the S7 Plasma Cutter CUT50. At around $150, it promises a pilot arc, dual voltage, and 50 amps of cutting power. But does it deliver? After testing it, here’s my take.

How the S7 Plasma Cutter CUT50 Works for Me

When I set up the S7 55A plasma cutting machine, I wasn’t sure what to expect. Budget cutters can be hit or miss. But after using it on different metals, I was surprised by how well it performed for the price. The S7 CUT50 feels like a manageable dragon for small projects.

What I Love About It

The S7 IGBT inverter plasma cutter has great features. It makes my work easier.

- Pilot Arc Technology – I can cut rusted or painted metal without touching it. This saves time and reduces wear on parts.

- High-Frequency Start – Fewer misfires. For quick repairs or art, it’s like a pocket-sized lightsaber.

- Dual Voltage Flexibility – It works on 110V in my garage or 220V in my shop. No adapter issues.

- IGBT Inverter Technology – It’s efficient and stable during long cuts. The arc stays steady, even on shaky generator power.

- Lightweight & Portable – The S7 is easy to carry. It fits in tight spaces.

- Decent Cutting Power – It cuts up to 3/8” steel well on 220V.

- Digital Display – The screen shows accurate amperage. Adjustments are easy.

- Easy Setup – I hooked it to my air compressor in 10 minutes. The air pressure sensor stops dry fires. Great for beginners.

How These Features Come in Handy for Me

This tool makes my work faster and smoother. I use the pilot arc to cut rusty or painted surfaces. It saves me time.

The high-frequency start gives me clean cuts every time. It’s great for quick jobs or creative work. I can switch between my garage and workshop with dual voltage. No extra steps are needed.

The IGBT inverter keeps the machine running well. It works even when the power is unstable. The tool is light and easy to move. It fits in tight spaces. I can cut thick materials with no trouble.

The digital display shows clear readings. I make quick adjustments.

Setup was easy. I connected it to my air compressor in minutes. The air pressure sensor helps me avoid errors. I use this tool for simple tasks and complex projects. It works well for me.

What Could Be Better

The S7 110V/220V plasma cutting tool has some areas to improve.

- Lower Than Advertised Amperage: The amperage is lower than advertised. It claims 55A, but my clamp meter showed 38A max, especially on 110V. It still cuts, but don’t expect industrial power.

- Short Cables: The cables are short. The work clamp and power cord are too short. I often use an extension cord, but it’s annoying.

- More Dross than Premium Models: It leaves more dross than premium models. The cuts have more slag, so I spend extra time cleaning edges.

- No Built-In Air Compressor: It doesn’t have a built-in air compressor. You need a separate one, which adds to the cost.

The Impact of These Limitations on My Work

These drawbacks aren’t deal-breakers, but they take some getting used to. The short cables limit mobility, but I zip-tie extensions to the torch. The dross? A small price for a $150 tool. I’ve had to tweak air pressure settings to reduce dross. For car repairs and DIY sculptures, it’s “good enough.”

My Overall Experience with the S7 Plasma Cutter CUT50

I’ve used the S7 IGBT plasma cutter CUT50 for months. For a budget cutter, it works better than I expected. It’s not as good as premium brands like Hypertherm. But for DIYers and hobbyists, it’s a solid choice.

I was most impressed by how well it cuts 1/8” to 1/4” steel. It even works well on 110V. The mix of pilot arc, portability, and low cost makes it a great addition to my workshop.

Recommendation

Buy this if:

- You’re a DIYer or hobbyist needing occasional cuts.

- Budget is tight, but dual-voltage flexibility matters.

- Rusty/painted metal is your nemesis (pilot arc FTW).

Skip this if:

- You’re cutting 1/2”+ steel daily.

- Clean, dross-free edges are non-negotiable.

For professionals who need top precision and power, a higher-end model might be better. But for its price, the S7 plasma cutter CUT50 is a great choice.

If you want a portable cutter under $500 that gets the job done, this one is worth a look!

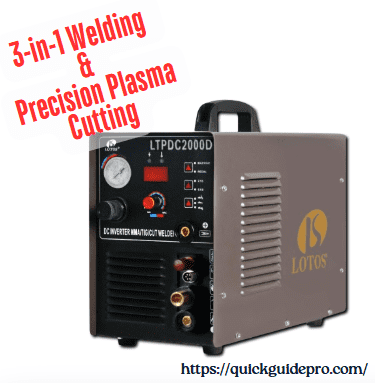

#4 LOTOS LTPDC2000D 2024 Upgraded 3 in 1

Specs

- Model: LTPDC2000D

- Dimensions: 19.5″ x 7.9″ x 14″

- Weight: 25.8 lbs (11.72 kg)

- Input Voltage: Dual voltage capability of 110-220 V, 1-PH, 50/60 Hz

- Power Supply Type: Inverter – MOSFET

Plasma Cutting:

- Output Current: 10-50 A

- Rated Input Current:

- 110 V: 50 A

- 220 V: 35 A

- Duty Cycle at 40°C (104°F):

- 60% @ 50 A

- 100% @ 35 A

- Gas Supply: Requires clean, dry, oil-free air

- Recommended Gas Inlet Flow Rate/Pressure: 3.6 scfm @ 65 psi

- Cutting Thickness:

- Max Ideal Clean Cut Thickness: 1/2″

- Max Severance Thickness: 3/4″

TIG Welding:

- Output Current: 15-200 A

- Materials: Suitable for welding steel, stainless steel, molybdenum, and other ferrous metals

- Duty Cycle at 40°C (104°F):

- 60% @ 200 A

- 100% @ 105 A

- No Load Voltage: 62 V

- Working Voltage: 16.9 V

- Gas Supply: Requires clean, dry, oil-free argon gas

- Starting Mechanism: High-Frequency Start (HF)

- Recommended Gas Inlet Flow Rate: 2-5 L/min

Stick Welding (MMA):

- Output Current: 15-200 A

- Materials: Suitable for welding steel, stainless steel, molybdenum, and other ferrous metals

- Duty Cycle at 40°C (104°F):

- 60% @ 200 A

- 100% @ 95 A

- No Load Voltage: 62 V

- Working Voltage: 25 V

- Starting Mechanism: High-Frequency Start (HF)

The LOTOS LTPDC2000D 2024 Upgraded is a machine that truly stands out. What makes the 2024 model special? It features a Newly Upgraded PC Board. This improves performance and durability. It ensures smoother operation and longer life.

Along with this, it includes a 50A non-touch pilot arc. This makes cutting effortless. It also offers improved precision with a 5/8” clean cut and 3/4” severance cut. The TIG and stick welding power is now 200A.

These upgrades make it faster, more efficient, and easier to use than the previous model. For me, this machine has been a game-changer. It delivers reliable results for a wide range of tasks.

How the LOTOS LTPDC2000D Works for Me

The 3-in-1 feature of this machine is a big plus. I don’t need separate tools for different tasks. Whether I’m cutting, TIG welding, or stick welding, it works well every time. The setup is simple, and the dual voltage (110V/220V) lets me work anywhere.

What I Love About It

The LOTOS LTPDC2000D is packed with features. It gives me power, precision, and ease of use. Here’s why I like it:

- More Power, Cleaner Cuts – The 2024 model is stronger. It has 25% more cutting power than other 50-amp cutters. It cuts 5/8-inch clean and 3/4-inch severance. That means I spend less time fixing rough edges.

- Non-Touch Pilot Arc – It cuts through rust, paint, and rough metal with ease. The pilot arc reduces slag, so the cuts are smooth. It also runs on safe compressed air instead of gas. The compact design and handle make it easy to carry.

- TIG Welding Precision – The 15-200AMP DC output makes TIG welding smooth. It works well with stainless steel and thin metals. The HF arc start helps me get clean welds. It even supports a foot pedal for better control (sold separately).

- Strong Stick Welding – Stick welding is steady and strong. The easy arc start helps me get going fast. The arc stays stable, and the welds go deep. It also works with different electrodes, so I can use it on many materials.

- Quick & Easy Setup – I can set it up in under a minute. It comes with a pre-installed NPT 1/4″ plug and an air filter regulator. I just connect it to my air compressor, and it’s ready to go.

- Great Support & Warranty – LOTOS offers lifetime technical support. It also has a 30-day money-back guarantee and a three-year limited warranty. Their U.S.-based support team is easy to reach.

- Comes Fully Equipped – The package has everything I need. It includes a power supply, plasma cutting torch, TIG torch, and stick electrode holder. It also comes with a ground clamp, air filter regulator, consumables, and a manual.

How These Features Come in Handy for Me

First, the 3-in-1 design saves me time. I don’t need to switch between machines. Whether I’m cutting metal or welding, it’s all in one place. This keeps my workspace neat and my workflow smooth.

The non-touch pilot arc is a lifesaver. It cuts through tough surfaces like rust and paint without a hitch. I don’t have to prep the metal much. This means less work and more time for the fun parts of my projects.

The TIG welding is precise. It’s perfect for thin metals and stainless steel. I get clean, strong welds every time. The option to add a foot pedal gives me even more control. This is great for detailed work.

Stick welding is just as good. The arc starts easy and stays steady. I can weld deep and strong without issues. It works with different electrodes too. This lets me tackle a variety of materials without hassle.

Setting up is a breeze. I can get it ready in under a minute. The pre-installed plug and air filter regulator makes it simple. I just connect it to my air compressor, and I’m good to go. No fuss, no delays.

The support and warranty give me peace of mind. Knowing I have lifetime technical help is a big relief. The three-year warranty and 30-day money-back guarantee show LOTOS stands by their product.

Everything I need comes in the box. I don’t have to buy extra parts or tools. This saves me money and time. I can start working right away.

In short, this machine makes my work easier, faster, and more fun. It’s reliable, powerful, and packed with features that fit my needs perfectly. It’s not just a tool—it’s a partner in my projects.

What Could Be Better

There are a few areas where I feel there’s room for improvement:

- Foot Pedal Not Included – For TIG welding, a foot pedal would help with heat control. It’s not a big issue, but it would make welding smoother.

- Size – It’s bigger than some other portable plasma cutters. If you need something lightweight, this might not be the best option.

- Accessories – The package could include more. A stronger ground clamp or a better welding torch would be nice additions.

The Impact of These Limitations on My Work

These small issues don’t really affect my work. The lack of a foot pedal for TIG welding isn’t a big problem. I can still get quality welds by adjusting the heat manually. The bulkier size is only a hassle in tight spaces, but for most jobs, it’s just fine. As for the accessories, they’re easy to upgrade on my own, so it’s not a dealbreaker.

My Overall Experience with the LOTOS LTPDC2000D

Overall, my experience with the LOTOS LTPDC2000D has been great. I’ve used it for months, and it hasn’t let me down. It makes my projects easier and more efficient. Most importantly, it gives pro-level results. I’ve cut thick steel plates and welded stainless steel with no trouble. It handles everything smoothly. Compared to other brands I’ve tried, this machine gives great value without losing quality.

Recommendation

I highly recommend the LOTOS LTPDC2000D to anyone who needs a reliable, versatile welding machine. Whether you’re a professional welder or a DIY enthusiast, this machine will not disappoint. If you’re looking to save space and money by having one machine that does it all—plasma cutting, TIG welding, and stick welding—then this is the machine for you. Don’t hesitate to give it a try; you won’t regret it!

#5 Reboot RBC6000DL Plasma Cutter

Specs

- Dual Voltage: 110/120V & 220/240V

- Output Current: Up to 60A

- Max Clean Cut: 5/8″ (16mm)

- Max Severance Cut: 4/5″ (20mm)

- Non-Touch Pilot Arc

- Digital Display

- Includes Accessories – Cutting torch, ground clamp, consumables, gas hose, air regulator

I was excited to try the Reboot RBC6000DL Plasma Cutter. This plasma cutting machine promises to offer both versatility and precision. It combines power, portability, and ease of use. It’s a great tool for both beginners and professionals.

Let’s take a closer look at how it performs in real-world conditions.

How the Reboot RBC6000DL Plasma Cutter Works for Me

From the moment I set it up, the Reboot RBC6000DL impressed me with how simple it was. It comes with a 120V plug and a conversion cord. Switching to 240V was easy if needed. I connected it to my air compressor quickly. Within seconds, I was ready to cut through metal. The setup was smooth, and the cutting quality blew me away.

What I Love About It

I’ve been thoroughly impressed with the Reboot RBC6000DL Plasma Cutter. Here’s what I love about it:

Non-Touch Pilot Arc: This feature made cutting through rusty or painted surfaces super easy. I didn’t need direct contact with the metal. This reduced slag and improved the cutting quality. It also helped extend the life of the consumables.

Powerful Cutting: With IGBT inverter technology, this cutter delivers 10-60A DC output. It handles clean cuts up to 5/8″ and severance cuts up to 4/5″ under 240V. This makes it perfect for tougher projects.

Voltage Conversion: I love how easy it is to switch between 120V and 240V. The conversion cord made the switch simple. Whether I was working at home, in the shop, or at a job site, it gave me great flexibility.

Quick Assembly: The quick couplings were a game-changer. I was able to connect everything in less than a minute. This saved me tons of time. It’s easy to get started and get to work.

Compact and Portable: Weighing just 8.2 pounds, this plasma cutter is easy to move around. It’s perfect for both large and small jobs. The portability made it simple to store.

Comprehensive Package: The included accessories were a huge plus. The plasma cutting torch, ground clamp cable, and air filter regulator saved me time and money. The extra consumables meant I could keep going without any interruptions.

Air Compressor Required: The 90 PSI, 60L/min requirement is pretty standard. It ensures the machine performs efficiently. You can easily hook it up to an air compressor and get to work quickly.

How These Features Come in Handy for Me

These features have made a big difference in how I use the Reboot RBC6000DL Plasma Cutter. The Non-Touch Pilot Arc helps me cut through rusty or painted metal without touching it. This reduces slag and gives me cleaner cuts. It’s a real time-saver, especially on tough surfaces.

The 10-60A DC output provides the power I need to cut through a variety of materials. Whether I’m cutting thick steel or lighter metals, it gives me smooth, precise cuts every time.

Switching between 120V and 240V is easy. This flexibility allows me to work anywhere, no matter the power source available.

The quick couplings make setup a breeze. I can get everything connected in seconds and get straight to work.

At just 8.2 pounds, this cutter is easy to move and store. It’s the perfect size for both job sites and smaller workspaces.

The included accessories are a huge bonus. The plasma cutting torch and ground clamp cable are top-notch, so I don’t have to buy extra parts.

With the 90 PSI, 60L/min requirement, it’s easy to connect to any air compressor. I can start cutting quickly, without any delays.

What Could Be Better

The Reboot RBC6000DL Plasma Cutter works great, but there are a few small areas where it could improve.

- Cutting Thickness Under 120V: At 240V, it cuts well. But at 120V, it only cuts up to 3/8” thick. This can limit work on thicker materials. Still, it’s good for most tasks.

- Lack of Digital Settings: It would be nice to have digital controls. Manual settings work fine, but digital options would make fine-tuning easier.

- Air Consumption: It needs 90 PSI and 60L/min of air. During heavy cuts, the air runs out fast. Saving more air would help on longer projects.

- Noise Levels: It can get loud, especially with thicker cuts. It’s not too bad, but a quieter machine would be better for indoor work.

The Impact of These Limitations on My Work

These small limits haven’t slowed me down. With a few tweaks, I still get great results.

The 120V cutting limit can be a hassle for thicker metals. But for most jobs, it works fine. When I need more power, I switch to 240V.

Manual controls work well, but digital settings would help with fine-tuning. Still, I get precise cuts with a bit of practice.

The air runs out faster on heavy cuts. I just make sure I have enough before starting. A little planning keeps things running smoothly.

The noise isn’t too bad, but it gets louder with thick cuts. It’s manageable, though a quieter machine would be a nice bonus.

My Overall Experience with the Reboot RBC6000DL Plasma Cutter

The Reboot RBC6000DL has been a solid tool for my projects. It’s simple to use and gives great results. I work with metal often, so I love its power and portability.

This cutter has made my job quicker and easier. Its features are useful, and it handles most tasks without trouble. I’ve used it on many projects, and it has never let me down.

Recommendation

The Reboot RBC6000DL is great for DIYers, hobbyists, and pros. If you cut metal for auto work, fabrication, or home projects, this tool is a smart choice. It’s light, strong, and simple to use. Both beginners and experts will find it handy.

If you need a plasma cutter that’s powerful yet budget-friendly, this one is a winner. Don’t hesitate—give it a try for your next project, and I’m sure you’ll be as impressed as I am.

#6 TOOLIOM 50A Non-Touch Pilot ARC Air Plasma Cutter

Specs

- Input Voltage: Dual 110V/220V

- Output Current: Up to 50A

- Duty Cycle: 60% at 50A

- Max Clean Cut: 1/2 inch (12.7mm)

- Non-Touch Pilot Arc

- Digital Display & Regulator:

- Weights: only 13 lbs

- Included Accessories: Plasma cutter, torch, work clamp, gas hose, 110V/220V adapter, and more!

I’ve tested many plasma cutters, from heavy-duty models like the LOTOS LTP5000D to pro-level models like the Bestarc BTC500DP. So, I was curious—could the TOOLIOM 50A keep up? Turns out, it did more than hold its own. This budget tool offers reliable performance without the hassle. It feels solid, works smoothly, and tackles tough jobs with ease. After testing several models, I found this one to be a great balance of power, precision, and value. Let me break it down for you.

How the TOOLIOM 50A Plasma Cutter Works for Me

When I first used the TOOLIOM 50A, I was impressed with it performance. It cut through different materials fast. Setting it up was easy, even for someone like me who’s used many machines. Whether I’m working on small projects or cutting thicker metals, it always works.

What I Love About It

The TOOLIOM Plasma Cutter has some standout features that make it an essential tool in my arsenal:

Let me share what impressed me the most.

Here’s why I love it:

- Up to 50A Cutting Power: You can cut thicker materials. The max severance cut is 4/5″ (20mm), and the clean cut is 1/2″ (12.7mm). You’ll get sharp, clear cuts every time.

- Built-in Air Pressure Regulator with LCD Screen: The LCD screen shows the air pressure value. You can read and adjust the pressure easily, giving you better control.

- Plug-in Air Filter Connector: The 1/4” quick connector is simple. Just plug it into your air compressor. No need for a complicated setup.

- Adjustable Post-Flow Time: You can adjust the post-flow time from 5 to 8 seconds. This cools down the welding head quickly, making your consumables last longer.

- 2T/4T Function for Comfort: The 2T/4T toggle gives you the freedom to pick your cutting mode. It’s perfect whether you’re cutting for a few seconds or a few minutes.

How These Features Come in Handy for Me

These features really make a big difference in my work. The 50A cutting power is perfect for thicker metals. It cuts through materials fast and clean. This saves me time and keeps the cuts sharp, even on tough jobs.

The air pressure regulator with the LCD screen is a great help. I can easily see the air pressure and adjust it. This makes it easy to control and reduces the chances of mistakes.

Setting up is fast and simple with the plug-in air filter connector. I just connect it to the air compressor and start working. No extra steps or tools needed.

The adjustable post-flow time is something I really like. It helps cool down the welding head quickly. This keeps the consumables lasting longer, so I don’t have to replace them as often.

The 2T/4T toggle gives me options for different cutting tasks. For quick cuts, I use 2T. For longer cuts, I switch to 4T. This makes it easier to work without getting tired.

These features make my job easier and faster. I can focus on the work, not on fixing problems or worrying about setup.

What Could Be Better

Here’s how it can improve while still performing well:

User Manual Clarity: The setup is simple, but the manual could be clearer. I spent time figuring out advanced features like air pressure adjustments and post-flow settings. A better guide would help new users save time.

Weight: The cutter is portable but feels a bit heavy. Moving it often can feel bulky. A lighter version would help, but it’s still manageable for most tasks.

The Impact of These Limitations on My Work

Here’s how these limitations affect my work:

The user manual could be clearer on some advanced features. It took me a little extra time to figure out the air pressure adjustments and post-flow settings. But, I was still able to get to work. A better guide would help save time when trying out new features. As for the weight, it’s not a dealbreaker for me. I find it manageable for most tasks. However, if I had to move it around a lot, a lighter version would make it easier to carry. Despite these small points, the TOOLIOM 50A still performs well and gives great value in my daily work.

My Overall Experience with the TOOLIOM 50A Plasma Cutter

After using the TOOLIOM 50A for over a year, it’s clear that this cutter is a winner.

What really impressed me about the TOOLIOM 50A is how simple it is to use. It’s not just for beginners—it’s reliable and effective for all kinds of jobs. I’ve worked on everything from small projects to tough, professional tasks. No matter what, this cutter performs well.

The biggest difference with this cutter is how it blends value and performance. You get strong cuts and an easy setup at a price that’s hard to beat. While other plasma cutters might struggle with clean cuts or overheat, this one keeps going strong. It’s also incredibly simple to use. I found it easy to get started, and it works just as well as more expensive models.

The TOOLIOM 50A is the perfect choice for anyone who wants a cutter that’s both reliable and affordable. It’s easy to set up, easy to use, and it gets the job done. If you need a plasma cutter that cuts cleanly and works hard, this is the one for you.

Recommendation

I highly recommend the TOOLIOM 50A Plasma Cutter. It’s great for hobbyists and pros. This tool is reliable, efficient, and versatile. It works well for home projects or tough workshop tasks. You’ll get the precision and performance you need.

If you want clean, easy cuts, this is the tool for you. It’s a top choice for high-quality results at a great price.

Ready to upgrade your cutting? The TOOLIOM 50A is perfect for DIY fans and pros alike. It offers precision and reliability. Get yours today and see the difference!

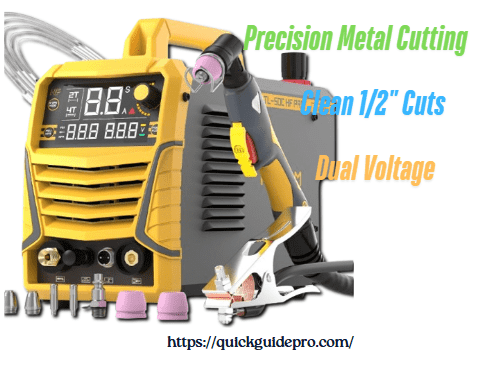

#7 ARCCAPTAIN CUT50 Plasma Cutter

Specs

- Dual Voltage: 110V & 220V

- Output Current: Up to 50A

- Duty Cycle: 60% at 50A

- Max Clean Cut: 1/2 inch (12.7mm)

- Non-Touch Pilot Arc

- Digital Display & Regulator:

- Safety Protections: Overcurrent, overload, and temperature control

- Weight: 13 lbs

- Included Accessories: Plasma cutter, torch, work clamp, gas hose, adapter, and more

When I first tried the ARCCAPTAIN Plasma Cutter, I was eager to see how it compared to others I’ve used. Its features stood out to me. After using it on a few projects, I’m excited to share my experience.

How the ARCCAPTAIN Plasma Cutter Works for Me

As a DIY enthusiast, I often find myself in need of cutting through various materials like mild steel, stainless steel, and even aluminum. The ARCCAPTAIN Plasma Cutter made this process incredibly easy.

What I Love About It

This plasma cutter really impressed me with its simplicity and efficiency. Here’s what I love most about it:

- Powerful Performance: With dual-voltage (110/220V) and advanced IGBT inverter technology, it cuts through steel, aluminum, and copper easily. The 1/2″ clean cut is great for all types of work.

- Easy Setup: Setting it up is fast. The plug-in air filter connector and built-in regulator take only 30 seconds. You can start cutting right away.

- Lightweight and Portable: It weighs just 13 lbs. The included strap makes it easy to carry and move around.

- Advanced Digital Technology: The large LED display shows clear data. You can adjust the post-flow time (5-15 seconds) for a clean cut. The 2T/4T toggle gives you more control for longer cuts.

- Safety and Durability: It meets TÜV and ANSI safety standards. The post-flow function cools the torch, helping your consumables last longer and saving you money.

How These Features Come in Handy for Me

These features make a big difference in my work. The dual-voltage design means I don’t have to search for the right outlet. The LED display makes it easy to check settings, even when I’m wearing safety gear. It’s lightweight, so I can easily carry it to different job sites. The cooling function helps extend the life of the parts, so I don’t have to replace them often.

What Could Be Better

The ARCCAPTAIN Plasma Cutter is great, but it could be better in a few ways:

- Torch connection: The PT31 torch works well, but it could last longer for heavy work.

- Setup: It’s easy to set up, but you’ll need to take time to get the air pressure right.

- Noise: It’s not too loud, but the fan could be quieter for a better work environment.

The Impact of These Limitations on My Work

These problems are small and don’t affect my work much. The torch works well for small and medium jobs. For bigger jobs, I’d like the torch to last longer. The noise and setup are small issues. But if you want something that’s quiet and easy to set up, keep this in mind

My Overall Experience with the ARCCAPTAIN Plasma Cutter

I’ve used the ARCCAPTAIN Plasma Cutter for a few months. It’s one of my favorite tools for cutting metal. The 50 Amp power and dual-voltage feature help me cut many materials. Whether I’m cutting steel for a DIY project or just working in the garage, it works great.

This cutter is more flexible and portable than others. The post-flow cooling and 2T/4T modes make it even better.

Recommendation

If you need a reliable and portable plasma cutter, I recommend the ARCCAPTAIN Plasma Cutter. It’s perfect for DIY enthusiasts, beginners, or anyone who wants to upgrade their tools. Get it now and take your cutting to the next level!

Quick Comparison Chart of 7 Best Plasma Cutters Under 500

Below is a detailed comparison chart of seven budget-friendly plasma cutters.

| Specification | LOTOS LTP5000D | Bestarc BTC500DP | S7 CUT50 | LOTOS LTPDC2000D | Reboot RBC6000DL | TOOLIOM 50A | ARCCAPTAIN CUT 50 |

|---|---|---|---|---|---|---|---|

| Cutting Capacity | Clean Cut: 5/8″ Severance: 3/4″ | Clean Cut: 1/2″ | Clean Cut: 1/2″ | Clean Cut: 5/8″ Severance: 3/4″ | Clean Cut: 5/8″ Severance: 4/5″ | Clean Cut: 1/2″ | Clean Cut: 1/2″ |

| Voltage | 120V/240V | 110V/220V | 110V/220V | 120V/240V | 110/120V or 220/240V | 110V/220V | 110V/220V |

| Arc Type | Non-Touch Pilot Arc | Pilot Arc (Air Sensor Technology) | IGBT (Non-Touch Pilot Arc) | Non-Touch Pilot Arc | Non-Touch Pilot Arc | Non-Touch Pilot Arc | IGBT (Non-Touch Pilot Arc) |

| Amperage | 50A | 50A | 55A | 50A (Plasma), 200A (TIG & Stick) | 60A | 50A | 50A |

| Duty Cycle | 60% at 50A | 60% at 50A | 60% at 50A | 60% at 50A (Plasma) | 60% at 60A | 60% at 50A | 60% at 50A |

| Max Cut Thickness | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 5/8″ | 1/2″ | 1/2″ |

| Power Source | AC/DC | AC | AC | AC/DC | AC | AC | DC |

| Weight | 22 lbs | 18 lbs | 16 lbs | 34 lbs | 25 lbs | 19.8 lbs | 21 lbs |

| Dimensions | 15.6 x 7.3 x 11.2 inches | 14 x 5.5 x 10 inches | 14.5 x 5 x 10 inches | 18 x 8 x 14 inches | 16.5 x 8 x 12 inches | 14.6 x 6.5 x 10 inches | 14.2 x 6.5 x 11 inches |

A Comparative Discussion of the 7 Reviewed Budget Plasma Cutters

When you’re looking for a plasma cutter under $500, these seven models stand out. The LOTOS LTP5000D is great for tough jobs. It cuts cleanly up to 5/8″ and can handle severance cuts up to 3/4″. Plus, it has dual voltage, making it very versatile. If you’re new to plasma cutting, the Bestarc BTC500DP is a good option. It gives smooth cuts and has air sensor tech and a digital display. But you might need extra consumables. The S7 Plasma Cutter (CUT50) is affordable. It works well for light to medium jobs but struggles with thicker metals.

If you want more than one tool, the LOTOS LTPDC2000D is perfect. It’s a 3-in-1 tool: plasma cutter, TIG welder, and stick welder. It’s a bit more expensive, but great for multitaskers. The Reboot RBC6000DL is powerful, with a 60A output, making it great for thicker metals. But it can get loud. The TOOLIOM 50A Plasma Cutter is easy to use with a post-flow gas feature. However, it lacks advanced options. The ARCCAPTAIN CUT50 Plasma Cutter is easy to handle with a large LED display and dual voltage. But it’s not ideal for heavy, regular use.

Choosing the right plasma cutter depends on what you need. Whether you need power for heavy tasks or an affordable cutter for lighter work, you’ll find the right one here.

Basic Features to Look for in Plasma Cutters Under $500

Picking the right plasma cutter is easy when you know what to look for. Budget-friendly models now come with great features. Some of these were only found in expensive machines before. To get the best value, focus on these key details.

- Amperage and Power

Why It Matters: Amperage controls cutting power, speed, and thickness.

✔️Adjustable Amps – Lets you cut different metals.

✔️Higher Amps (50A+) – Cuts thick metal fast.

✔️Dual Voltage (110V/220V) – Works in home and shop outlets.

✔️Energy Efficiency – Uses less power while cutting strong.

- Cutting Ability

Why It Matters: The right cutter gives smooth, clean cuts.

✔️Max Cutting Thickness – Most budget models cut up to ½ inch.

✔️Clean vs. Severance Cuts – Clean cuts look smooth. Severance cuts push the limit.

✔️Duty Cycle – A higher duty cycle (like 60% at 50A) means longer work time.

- Portability and Design

Why It Matters: A light cutter is easy to move and store.

✔️Compact & Lightweight – Great for small spaces or travel.

✔️Comfortable Handle – Easy to carry with less strain.

✔️Strong Metal Case – Protects parts for long-lasting use.

- Torch and Consumables

Why It Matters: A good torch gives better control. Strong parts last longer.

✔️Pilot Arc – Cuts without touching metal, saving parts.

✔️Drag-Cutting – Lets you move the torch along the metal.

✔️Long Torch Cable – Gives more space to move while cutting.

- Easy Controls

Why It Matters: Simple settings make cutting easy.

✔️User-Friendly Dials – Quick and easy to adjust.

✔️Fast Setup – Plug-and-play models save time.

✔️2T/4T Modes – 2T for short cuts, 4T for long, steady cuts.

- Safety Features

Why It Matters: Safety features keep you and the machine safe.

✔️Overheat Protection – Stops damage from high heat.

✔️Air Pressure Regulator – Keeps airflow steady for better cuts.

✔️Strong Shields & Case – Protects from sparks and heat.

- Air Supply Needs

Why It Matters: The right air pressure makes better cuts and saves parts.

✔️Built-in vs. External Compressor – Some models have built-in air; others need an external source.

✔️PSI and CFM Ratings – Check air pressure to match your cutter.

✔️Moisture Filters – Keeps water out for smooth performance.

- Warranty and Support

Why It Matters: Good support means less stress if problems come up.

✔️At Least 1-Year Warranty – Covers repairs and defects.

✔️Easy-to-Find Parts – Replace worn-out parts without hassle.

✔️Customer Support – Quick help for troubleshooting.

To find the best plasma cutter under $500, focus on power, ease of use, and portability. A light design makes moving easy. Simple controls help you cut better. Features like pilot arc and drag-cutting improve performance. A strong, user-friendly model will last years. Keep these details in mind for a top-quality cutter that fits your budget.

FAQs About Best Plasma Cutter Under $500

Here are answers to some of the most common questions to help you make the right choice.

1. Can a budget plasma cutter handle thick metal?

Yes, many affordable plasma cutters can cut up to 1/2-inch steel. Look for models with at least 50 amps for better performance.

2. Are cheap plasma cutters reliable?

Many budget plasma cutters offer great performance. Look for durable builds, dual voltage, and good reviews for reliability.

3. Do I need an air compressor for a plasma cutter under $500?

Most plasma cutters need an external air compressor, but some have built-in air supplies. Check the specs before buying.

4. What safety gear should I use with a plasma cutter?

Wear a welding helmet, gloves, and flame-resistant clothing. Proper ventilation is also essential to avoid harmful fumes.

My Final Thoughts About Best Plasma Cutter under 500

You can get a good plasma cutter for under $500. These tools work great for both beginners and pros. We found that even cheap models now have features that were once only found in expensive ones. Safety, precision, and portability are now standard in budget-friendly cutters.

Pick a plasma cutter that fits your needs. Beginners should choose ones with simple controls and safety features. If you’re more experienced, find lightweight cutters with good cutting power. Remember to keep your cutter clean and set the PSI right to make it last longer.

Here are the main things to check before buying:

- Check if the power fits your workspace

- Find out the maximum cutting thickness

- Make sure the duty cycle works for your job

- Look for clear manuals

- Check the warranty and parts availability

Start simple, maintain your tool, and always follow safety rules. The right plasma cutter will help you cut well for years and still stay within budget.

I’m Ivan D. Mitchell. I’m the Chief Engineer, Manufacturing Engineering Tool and Launch, specialising in automotive equipment design and build which meets World Class Manufacturing methodology. I have 15 years of work experience as a Tooling Specialist on some of the leading automotive manufacturing companies. When I launched this site, I wanted to create a platform where you’ll get everything about tools in one place. I also wanted to share my experience in the tool industry. I’ll do my best to share the information you need to truly make your tool using experience better. I hope you find our guides, reviews, information HELPFUL. If you have any inquiries, I’m always here to help you.