The plasma cutting method is highly efficient and faster to cut any conductive metal.

One thing that makes this process highly efficient is that plasma flame can get extremely hot over a very short time.

Wondering how hot is a plasma cutter?

Here lies the answer!

In this post on “how hot are plasma cutters” I’ll explain this with many interesting facts.

So, continue reading.

How Hot Is a Plasma Cutter?

The plasma cutter arc is extremely hot, but it’s not something we can compare to a flame of a furnace. It’s so hot beyond what we can really comprehend.

So, what is the temperature of a plasma cutter?

In respect to this, a plasma flame can reach an intense and terrifying temperature of 25, 000-degree Celsius.

The core temperature of plasma flame ranges from 11,000° – 14,500° Fahrenheit.

To imagine how intense this temperature is, we can compare it to the heat from Oxy-fuel flame.

In general, an Oxy-fuel machine can produce a flame with 5,000-degree Celsius (9000-degree Fahrenheit). If you compare it to oxy-acetylene flame, the Plasma cutting arc is approximately 5 times hotter than that of Oxy-fuel.

How hot is plasma in Fahrenheit?

It’s 45,000-degrees in Fahrenheit.

Is a Plasma Cutter Hotter than the Sun?

So, how does this tremendous temperature of a plasma cutter compare with various truly astronomical temperatures?

The sun is a ball of different gas with different temperatures at different times. So, comparing the temperature of a plasma cutter to that of the sun won’t provide an apt answer to this question.

However, we can have an idea about the temperature of a plasma and the sun.

The average temperature of the sun’s surface is about 5505-degree Celsius (which is 9941-degree in Fahrenheit). As mentioned above, plasma arc temperature is 25,000-degree Celsius (which is 45,000-degree in Fahrenheit).

To put this into perspective, it’s proven that the plasma cutter flame is certainly hotter than the surface temperature of the sun. Plasma is almost four and half times hotter than the surface of the Earth.

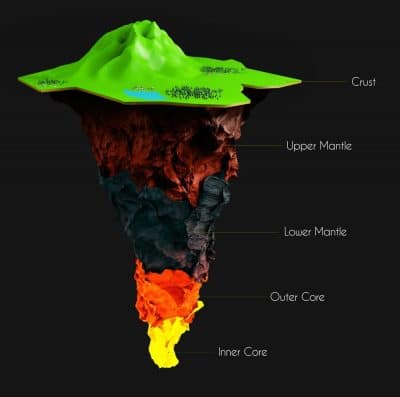

Is Plasma Cutter Flame Hotter than the Earth’s Core?

The Earth’s core is hotter than the Sun. Scientists have proved that the temperature of the hottest region of our earth core is about 6000-degree Celsius (which is 10,800-degree in Fahrenheit).

Taking into account the plasma flame temperature (25,000-degree Celsius), it’s obvious that the plasma flame is hotter than the Earth’s core.

The plasma arc is about 4.2 times hotter than the core temperature of the Earth.

Why Is Plasma So Hot?

From our above discussion, we’ve found that plasma is hotter than the sun and even the core of the earth.

So, what is the reason behind plasma flame being hotter than anything else?

Let’s explain.

What is plasma?

A plasma cutter machine generates an extremely hot, electrical channel of ionized gas which is known as plasma.

The fourth state of matter is plasma.

When a matter changes from solid to liquid and liquid to gas, its molecules generate heat. When the gas molecules get excited, they become hyperactive.

When superheated, the electrons from gas are ripped away from the atoms and form an ionized gas called plasma.

The increments of temperature between the transition of each state of matter increase significantly. For example, to turn a solid into liquid it takes just 2-degree F. To turn the liquid into a gas, it takes 212-degree F. These increments increases further by over 10,000 to form plasma. The plasma jets reaches to 40,000-degree Fahrenheit or 25,000-degree Celsius.

How Does a Plasma Cutter Work?

In a plasma cutting system, the cutter sends an electrical arc through plasma cutter gas (either argon, nitrogen, or oxygen). As a result, the heat levels rapidly increase to a point where it goes beyond the three states, becomes ionized, electrically conductive, and finally becomes plasma.

The machine then uses the plasma to transfer the energy to the electrically conductive metal. It sends an electric arc through the charged gas and is controlled through a narrow opening of the nozzle.

This method results in a fast and clean cutting process of metal.

Thus, a plasma cutter makes cutting through almost any conductive materials a breeze.

A handheld plasma cutter can cut 200 inches of material per minute.

How Can You Modify the Heat of the Plasma?

Although a plasma cutter flame could get intensely hot, you can control the unit at different heat levels according to the type of material and its thickness.

The plasma flame temperature mentioned above is only the maximum. You don’t need to use the maximum heat setting of a plasma cutter all the time.

Conveniently, you can lower the temperature by adjusting the system’s setting to suit your needs, especially if the metal you’re cutting is not very thick.

I recommend keeping the temperature setting as low as possible for safer operation and to cut down the cost of your electricity bill. Never leave the system running for too long.

Plasma cutter systems come in different types and each includes different temperature settings. So, you should get the right plasma cutter for your metalworking.

How Hot Is a Plasma Cutter- My Parting Words!

Having said all these, plasma flame is the hottest thing ever. It is even hotter than the Earth’s core and the Sun.

So, be sure to wear all kinds of safety equipment. Wear protective clothing. Use a protective shield for your face and head as well. I recommend wearing a welding cap/ hat underneath your welding helmet for full protection.

The plasma flame is so bright and intense that looking at the arc directly without keeping your eyes protected can lead to permanent blindness.

Shield your eyes with goggles that have the right shade of safety lenses. Many auto-darkening welding helmets are available that darken to correspond to your specific requirements.

I’m Ivan D. Mitchell. I’m the Chief Engineer, Manufacturing Engineering Tool and Launch, specialising in automotive equipment design and build which meets World Class Manufacturing methodology. I have 15 years of work experience as a Tooling Specialist on some of the leading automotive manufacturing companies. When I launched this site, I wanted to create a platform where you’ll get everything about tools in one place. I also wanted to share my experience in the tool industry. I’ll do my best to share the information you need to truly make your tool using experience better. I hope you find our guides, reviews, information HELPFUL. If you have any inquiries, I’m always here to help you.