So, have you decided to purchase a welding cap but are not sure what size would fit your head?

I understand the struggle of finding the perfect fit welders cap when shopping online. Because sometimes your cap can be too tight and sometimes too large to fit comfortably on your skull.

That’s why I hope my write-up on how to measure welding cap size will help ensure you get the perfect fit.

Table of Contents

Welding Cap Measurements

Comfort is one of the main considerations while purchasing a welding cap. It should fit nicely and comfortably on your head.

You don’t want to wear a cap all day long that is too tight or too loose on your head because it may be uncomfortable, which may cause hindrance during your welding. Moreover, this headwear is meant to be protection for your head, ears, and neck from flying welding sparks.

To ensure your weld cap functions as intended, you must choose the right size cap.

A common misconception is that your weld cap size is the same as your baseball cap. This is not true when it comes to buying the right size cap for welding. Sometimes the welding cap size chart may vary, so measuring your head is important.

To figure out what size cap you need, you have to measure-

-the circumference of your head

-Your crown height.

Now, let’s measure for size.

Don’t worry; it’s easy.

What you’ll need:

- You’ll only need a flexible measuring tape or tailor’s tape.

The tape must be soft.

Don’t use a metal tape measure.

If you don’t have a measuring tape, you can use a non-stretchable string.

** Do not try to measure your head with a metal tape measure!

How to Measure Welding Cap Size- Steps-By-Step Guidelines

By measuring your head circumference, you can figure out your required finished measurement of the band of the cap.

Measuring Head Diameter

Step 1: Hold one end of the tape measure (or the string) to the center of your forehead, where you want the cap band to lie.

Step 2: Wrap the tape around your head until your return to the starting point. The tape placement should be just above your eyebrow and ears but in a position that would be comfortable for a cap to rest. It should also be over the natural bump at the back of your head.

** If you prefer your cap to cover your ears, include them in the measurement.

Ensure the tape measure is flat on your head and isn’t twisted.

Do not pull the tape too tightly so that you stretch the tape. Ensure the tape is snug around your head but not too tight. It should be comfortable and just fitted enough to stay put.

Step 3: Carefully note down the measurement where the tape meets. Try to write the reading in inches as that is the most common method for measuring head circumference.

This is your weld cap size.

**Cotton welding cap may shrink after the first wash. So, check if the construction materials and come pre-washed or not.

If it comes pre-washed, you don’t need to add extra numbers thinking the cap with this measurement will shrink after washing and be tight.

** If you use a string instead of the tape measure, lay the string flat on a ruler to get the measurement.

Step 4: Use the size chart to determine which size will be your best fit. Choose the larger size closest to your actual measurement if you’re between sizes.

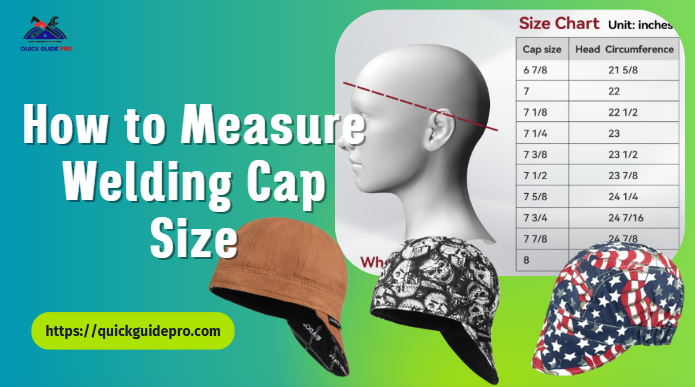

Welding Cap Sizing Chart

Here is the handy sizing chart that converts your measurements in inches to the centimeter, USA, English, and French welding cap measurements.

| Inches | Centimeters | USA Size | English Size | French Size | S/M/L |

| 19.52 | 50 | 6-1/4 | 6-1/8 | 1-1/2 | Child |

| 19.91 | 51 | 6-3/8 | 6- 1/4 | 2 | Child |

| 20.30 | 52 | 6-1/2 | 6-3/8 | 2-1/2 | XS |

| 20.70 | 53 | 6-5/8 | 6- 1/2 | 3 | XS |

| 21.09 | 54 | 6-3/4 | 6- 5/8 | 3-1/2 | S |

| 21.48 | 55 | 6-7/8 | 6- 3/4 | 4 | S |

| 21.88 | 56 | 7 | 6-7/8 | 4-1/2 | M |

| 22.27 | 57 | 7-1/8 | 7 | 5 | M |

| 22.66 | 58 | 7-1/4 | 7-1/8 | 5-1/2 | L |

| 23.05 | 59 | 7-3/8 | 7-1/4 | 6 | L |

| 23.45 | 60 | 7-1/2 | 7-3/8 | 6-1/2 | XL |

| 23.84 | 61 | 7-5/8 | 7-1/2 | 7 | XL |

| 24.23 | 62 | 7-3/4 | 7-5/8 | 7-1/2 | XXL |

| 24.62 | 63 | 7-7/8 | 7-3/4 | 8 | XXL |

| 25.02 | 64 | 8 | 7-7/8 | 8-1/2 | XXXL |

*Many welding cap brands have slight variations in their cap measurements and sizes.

*Not all brands include a size chart on their websites. These measurements should work for most welding caps.

Measuring Crown Height/ Cap Depth

Cap depth is labeled ‘high crown’ or ‘low crown.’

Crown height refers to the distance from the peak of your head to the band’s bottom edge.

Step 1: Measure from the highest peak of your head downwards your ears. Stops where you want the bottom edge of the band to be.

Step 2: Note down the reading.

*If you have an existing/ old cap that fits fine, lay it flat on its side. Measure the distance from the top of the crown to the bottom of the band.

Welding caps are available in different depths.

| Crown Depth | Description |

| 6-inch (shortest) | – |

| 6-1/2 inches (low crown) | It is a traditional fit that sit at the top edge of the ears like a baseball cap. |

| 7-inch (Medium crown) | Covers up to the middle of the ears |

| 7-1/2 inches (high crown) | Covers all of your ears |

| 8-inch | It is a traditional fit that sits at the top edge of the ears like a baseball cap. |

**Everyone is different, so the same crown depth may not fit in the same way for everyone.

Brim Length

Brims also come in different lengths.

- 2-inch: It is the shortest brim size. It is perfect if you prefer a smaller size or don’t need a brim in your way,

- 2-1/2 inches: It is the standard brim length. It fits nearly everyone.

- 3-inch: It is a popular size. 3” brim provides sufficient coverage of the neck and ear.

- 3-1/2 inches: It is perfect if your work demands a longer brim.

Final Thoughts: How to Measure Welding Cap Size

After reading this write-up, no one should be wondering how to measure welding cap size.

But I want to remind you that you should buy a good quality welding cap specially designed to wear during welding.

Don’t forget to wear your weld cap properly.

I’m Ivan D. Mitchell. I’m the Chief Engineer, Manufacturing Engineering Tool and Launch, specialising in automotive equipment design and build which meets World Class Manufacturing methodology. I have 15 years of work experience as a Tooling Specialist on some of the leading automotive manufacturing companies. When I launched this site, I wanted to create a platform where you’ll get everything about tools in one place. I also wanted to share my experience in the tool industry. I’ll do my best to share the information you need to truly make your tool using experience better. I hope you find our guides, reviews, information HELPFUL. If you have any inquiries, I’m always here to help you.