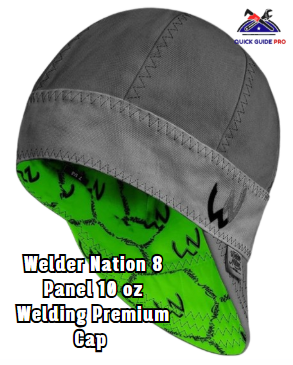

So, you purchase a comfortable and cool design welder’s cap.

Great!

The weld cap is a part of the welder’s uniform. It protects your hair and scalp from getting burned by welding sparks when you’re welding. It also protects your neck, collar area, and ears from the welding sparks that fly all around them.

I’ve found that people, especially the new welders, wear their weld caps with the bill in front, like a baseball cap. Unfortunately, it serves no purpose except to make a style statement.

But you need to wear it properly so that you’re using it for what it’s meant for.

No worries, I’ll share with you all the ways to wear a welding cap through this write-up.

So let’s get into it!

Table of Contents

Welders Cap Parts

If you are curious, here are the parts of a weld cap:

- The main part of a welder’s cap is the skull bucket that covers the hair and scalp. A flame-retardant welding cap blocks fire-causing sparks that could otherwise burn your hair and skin.

- The other part is the bill (also called brim, visor, or peak). Some weld caps have soft and short bills, while others have hard and longer bills.

A short and soft bill is easier to fit underneath a welding helmet or welding hood. A long bill that protrudes straight out is somewhat difficult to fit under a welding helmet.

A longer, stiffer bill with a slight downward angle readily works to protect the welder’s neck and ears while easily staying tucked away.

How to Wear Welding Cap Properly- 3 Ways for Maximum Protection and Comfort

This protective wear is available in different sizes, designs, and shapes. Some have a general crown like a non-welding cap, whereas others have a high crown. Some caps cover the skull only, while others have flaps to cover the collar and neck area.

When choosing a weld cap for yourself, make sure it is perfectly sized to fit comfortably and move around to adjust when needed.

To wear a weld cap correctly, consider how and in which position you are welding.

Here are the three ways to wear a weld cap.

1. How to wear a welding cap while welding flat

If you’re welding flat, wear the cap with the bill straight back and with a little bend of the bill. The slightly folded bill will help to catch the flying sparks in here and let them cool off before they drop down to the back of your shirt. You know that molten metal sparks going down your shirt or neck may cause burn injury.

In addition, wearing a weld cap with the bill in the rear of your head is the best way to combine it with a face shield or welding helmet.

2. How to wear a welding cap while welding horizontal position

If you’re welding in the horizontal position and wearing a deeper or high crown weld cap, you can pull down the cap over your exposed ear area to protect your ear from spattering.

3. How to wear a welding cap while welding overhead

If you’re doing overhead welding, you need to protect your neck and head from the flying sparks. This time, adjust the cap to have the bill at the back of your head.

4. How to wear a welding cap while welding at a one-sided angle

Likewise, if you’re welding on the one-sided angle, notice which of your ears and chin are facing up. Wear the cap sideways so that the bill is over that ear to protect your ear from the hot, molten metal.

Final Thoughts: How to Wear Welding Cap

To sum up, consider your position while welding and put the bill of the cap wherever you need to.

In this post, I have shared 3 ways for how to wear welding cap. I hope these come in handy.

Keep in mind that a welder’s cap is protective headgear. An ordinary cap or hat won’t be able to protect your head when welding or plasma cutting. So, it is important to use a welding cap that has been specifically designed for welding.

Don’t just throw it on—wear it right to stay safe and focused at work. Follow the simple steps that I’ve discussed above. Protect your head, wipe away sweat, and avoid painful burns!

Thanks a lot for reading till now.

I’m Ivan D. Mitchell. I’m the Chief Engineer, Manufacturing Engineering Tool and Launch, specialising in automotive equipment design and build which meets World Class Manufacturing methodology. I have 15 years of work experience as a Tooling Specialist on some of the leading automotive manufacturing companies. When I launched this site, I wanted to create a platform where you’ll get everything about tools in one place. I also wanted to share my experience in the tool industry. I’ll do my best to share the information you need to truly make your tool using experience better. I hope you find our guides, reviews, information HELPFUL. If you have any inquiries, I’m always here to help you.