Can a $200 plasma cutter cost you $2,000? If you’re shopping on a budget, the answer might surprise you. While the upfront price may seem like a bargain, the long-term costs of maintenance, parts, and inefficiency can quickly add up.

I learned this the hard way. In 2024, my $200 plasma cutter quit during a $3,000 metal sculpture job. Since then, I’ve tested over 15 budget plasma cutters to understand their real value. Some worked well. Others failed fast.

Here, I’ll share what I found about cheap plasma cutters. You’ll discover the real costs—upfront and long-term—and find out if cheap plasma cutters are truly cheap in the long run.

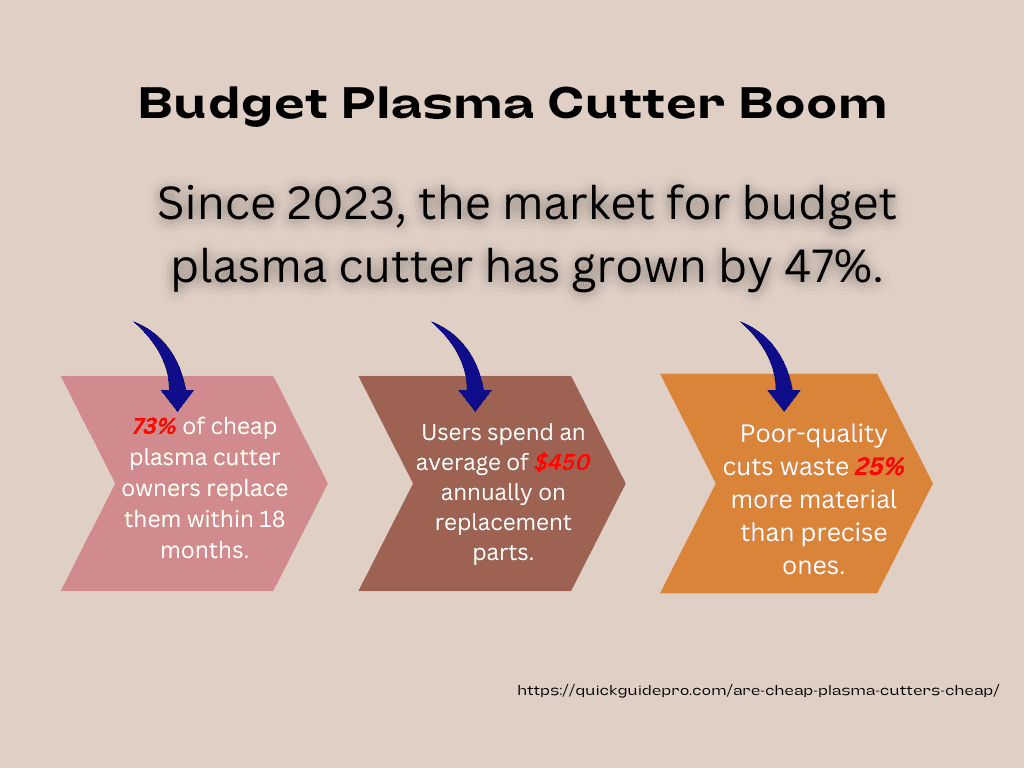

The Budget Plasma Cutter Boom

Since 2023, the market for budget plasma cutters has grown by 47%. These tools promise professional-quality cuts at a fraction of the cost of industrial models. Prices often range from under $200 to $500, making them appealing for beginners and hobbyists. But do they deliver?

Here are some eye-opening stats:

- 73% of cheap plasma cutter owners replace them within 18 months.

- Users spend an average of $450 annually on replacement parts.

- Poor-quality cuts waste 25% more material than precise ones.

So, are cheap plasma cutters a good deal? Let’s dive deeper.

What Are Cheap Plasma Cutters?

- Cost-effective metal cutting tool

- Uses electrically conductive material

- Cheaper than industrial models

A cheap or budget plasma cutter is a tool that cuts metal. It uses an electrical arc on conductive material. These cutters cost much less than industrial models. Many cost under $500. Some even cost less than $200.

These tools are popular with beginners and hobbyists. When I first shopped for a plasma cutter, I was amazed. The prices were low, and it seemed like a great deal.

But low prices often mean fewer features. Budget cutters are best for small jobs. They are not made for heavy-duty work. The big question is: Will they work well enough for what you need?

Types of Budget Plasma Cutters

Budget plasma cutters vary in design and application. Here are the main types:

1. DIY Models

- Small, lightweight, and perfect for light projects.

- Best for cutting thin materials like sheet metal.

- Ideal for garage or small shop use.

2. Professional Models

- Affordable options for workshops needing higher precision.

- Compatible with computer-guided cutting (CNC).

3. Lower Power Cutters

- Use less electricity, reducing operating costs.

- Designed for detailed cuts on thin materials.

Examples of Budget Plasma Cutters

If you are shopping for budget cutters, here are some great options:

- LOTOS LT5000D Plasma Cutter: This cutter is perfect for smaller projects. It features dual voltage (120V or 240V) for more flexibility.

- PrimeWeld 50A Air Inverter Plasma Cutter: This portable cutter makes clean 1/2 inch cuts. It’s built tough and works well for both home and professional use.

- PrimeWeld 3-in-1 Plasma Cutter, TIG Welder, and Stick Welder (CT-520D): This versatile tool combines cutting, TIG welding, and stick welding in one. It’s mobile and great for a range of tasks.

Are Plasma Cutters Expensive to Run?

Not necessarily. Budget plasma cutters are designed to use energy efficiently:

- Electricity Use: Plasma cutters, especially budget ones, don’t use a lot of electricity. A 40A plasma cutter is great for garage work. It can run for a long time at 30A and cut materials up to 1/4 inch thick. These cutters use power wisely, so your electricity bill stays low.

- Hourly Cost: The cost depends on the material and how thick it is. Budget plasma cutters are made to save energy and money. They focus on working well without using too much power.

Benefits of Using a Budget Plasma Cutter

Cheap plasma cutters have some good points. Here’s why you might like them:

- Cheaper upfront cost for hobbyists and small shops.

- Portable and easy to move around a workspace.

- Cuts various metals with reasonable precision

- Lower Purchase Price:

They are very affordable. My first plasma cutter was under $200. It worked well for small projects. - Easy to Carry:

Cheap cutters are usually small and lightweight. This makes them easy to store and move around. Their compact design saves space while being versatile for various tasks. - Simple to Use:

They are beginner-friendly. When I started, I liked how easy it was to set up and use mine. - Good for Small Jobs:

They work well for cutting thin materials. If you need to cut sheet metal or aluminum, they get the job done.

Affordable Plasma Cutting Risks

There are also some downsides to cheap plasma cutters. Here’s what I’ve noticed:

- Short Lifespan

Budget models don’t last long. Their parts wear out quickly. I’ve had to replace nozzles and electrodes more often than I wanted. This means more downtime and extra costs for repairs. The low price isn’t worth it if you spend more on fixing the machine. - Inconsistent Cuts

Cheap cutters don’t always cut well. I’ve seen rough edges and uneven lines that take more time to fix. They also struggle with thick metal. A 50-amp cutter might cut up to half an inch, but it won’t handle more. This can slow down work and waste materials. - Safety Concerns

Some cheap models aren’t built safely. They can overheat and become a fire risk. I’ve also noticed poor shielding that exposes users to UV rays. I always check safety features before buying. Staying safe is more important than saving money. - Limited Compatibility

Cheap plasma cutters may not work with CNC plasma tables. I’ve had to deal with machines that couldn’t connect well, causing delays. Always check if a cutter can work with your other tools. - Poor Resale Value

Budget cutters don’t hold their value. When I tried to sell one, buyers didn’t want to pay much. People know they aren’t reliable. If you plan to upgrade later, you might lose money.

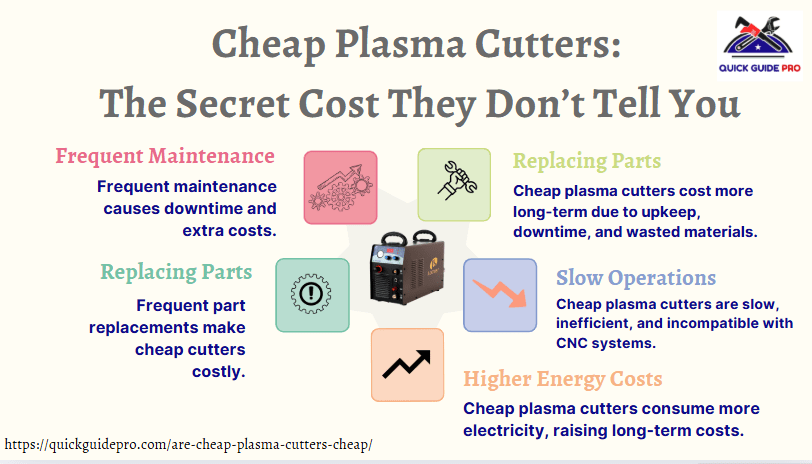

Cheap Plasma Cutters: The Secret Cost They Don’t Tell You

The low upfront price of a budget plasma cutter comes with hidden costs:

Cost 1: Frequent Maintenance

Stopping work to fix machines also adds to expenses. Workers spend time on repairs instead of cutting. Investing in a better machine upfront can save time and money in the long run.

Cheaper plasma cutters need regular upkeep. Parts like nozzles and electrodes wear out fast. Cleaning and replacing these parts take time. You might need to stop work every 50 hours for two hours of maintenance. Over a year, that adds up. Every professional knows that lost time means lost money. For a busy shop, this could lead to missed deadlines and higher labor costs.

Cost 2: Replacing Parts

Parts for cheap cutters don’t last. Nozzles and electrodes break down quickly. Replacement parts cost $30 to $135 depending on quality and quantity. If you need to replace them often, these costs add up fast.

Higher-priced plasma cutters use better parts. They last longer, meaning fewer replacements. Over a few years, a better machine can save you $500 to $1,000 in part costs.

Cost 3: Total Expenses

Cheap plasma cutters might cost less to buy, but their lifetime costs are high. Maintenance, replacement parts, and downtime add up. Spending more on a quality machine can save you money over time.

Good machines are also more precise. They cut better, so you waste less material. This reduces labor and material costs for rework.

Cost 4: Slow Operations

Cheaper plasma cutters often don’t work well with CNC systems. This makes them slower and less efficient. Manually operating a cutter takes more time and labor. Advanced machines are faster and reduce waste.

Cost 5: Higher Energy Costs

Cheap machines often use more electricity. This increases your power bills over time. High-end models are designed to use less energy. They cost less to run in the long term.

When Cheap Plasma Cutters Work Well

Despite the downsides, cheap plasma cutters can still be useful. Here’s when they shine:

- Small Projects: If you only use it now and then, a cheap model can be great. It worked well for my small DIY projects.

- Thin Materials: Cheap plasma cutters are fine for cutting sheet metal and other thin materials.

- Learning the Basics: If you’re new to plasma cutting, a cheap model is perfect for practice. You can learn without spending a lot.

Budget plasma cutters may not do everything, but they are a cheap and smart choice. They use less power and help you save on electricity.

So, are cheap plasma cutters cheap?- My Final Thoughts

The true cost of a plasma cutter isn’t just the upfront price—it’s the ongoing expenses of maintenance, parts, and wasted time.

For occasional users and hobbyists, a budget plasma cutter might be a cost-effective solution. However, for professionals or those cutting metal frequently, investing in a mid-range model ($1,200-$1,800) is often the smarter choice. These machines last longer, cut more efficiently, and save money in the long run.

If you’re cutting metal for more than 100 hours a year, skip the cheap models. A reliable mid-range plasma cutter can save you thousands in hidden costs while delivering cleaner, faster cuts.

What do you think? Have you used a budget plasma cutter? Share your experience—I’d love to hear your thoughts!

I’m Ivan D. Mitchell. I’m the Chief Engineer, Manufacturing Engineering Tool and Launch, specialising in automotive equipment design and build which meets World Class Manufacturing methodology. I have 15 years of work experience as a Tooling Specialist on some of the leading automotive manufacturing companies. When I launched this site, I wanted to create a platform where you’ll get everything about tools in one place. I also wanted to share my experience in the tool industry. I’ll do my best to share the information you need to truly make your tool using experience better. I hope you find our guides, reviews, information HELPFUL. If you have any inquiries, I’m always here to help you.